BLOGS

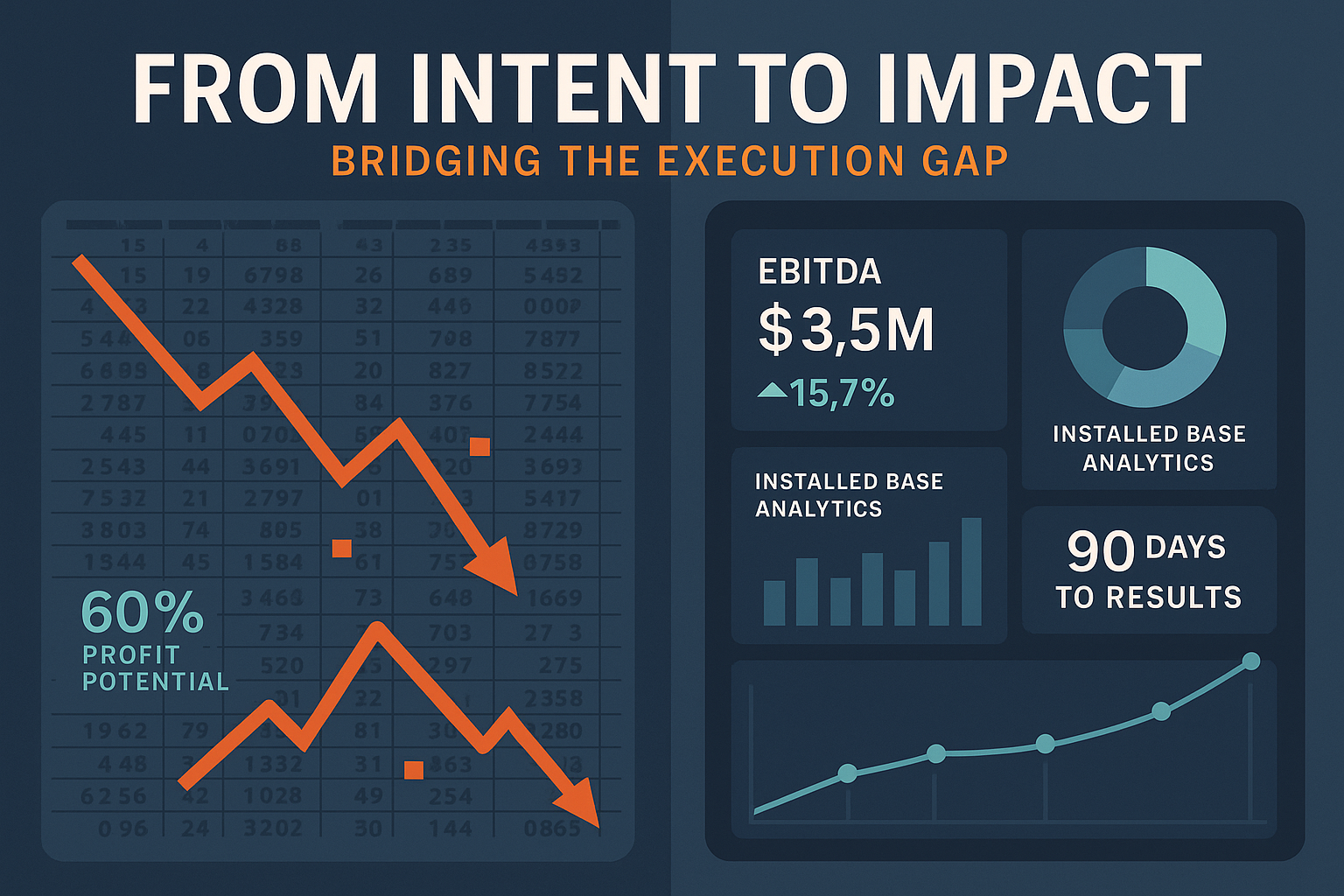

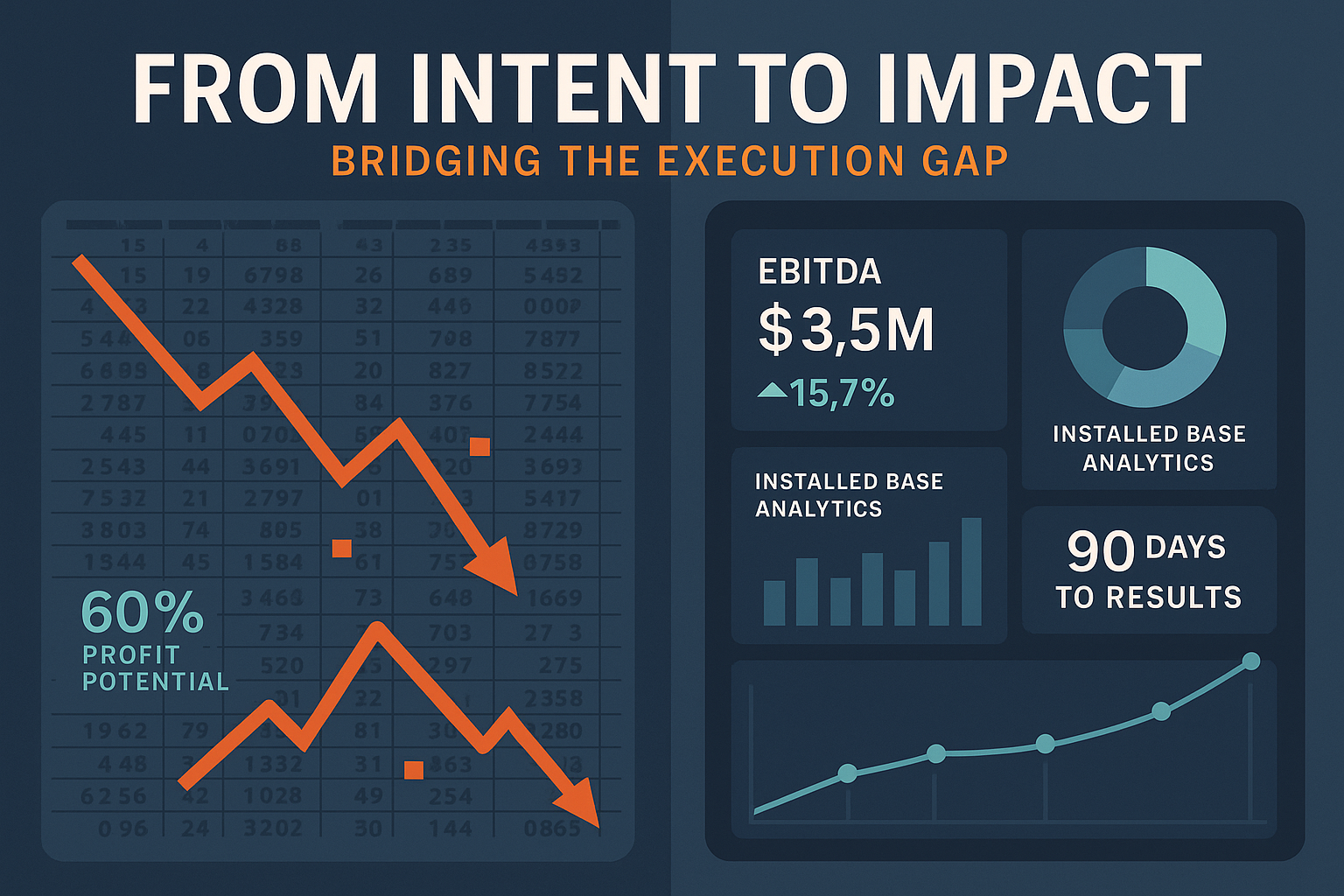

From Deal Thesis to EBITDA Reality: Why PE-Backed OEMs Must Fix Their Aftermarket Execution

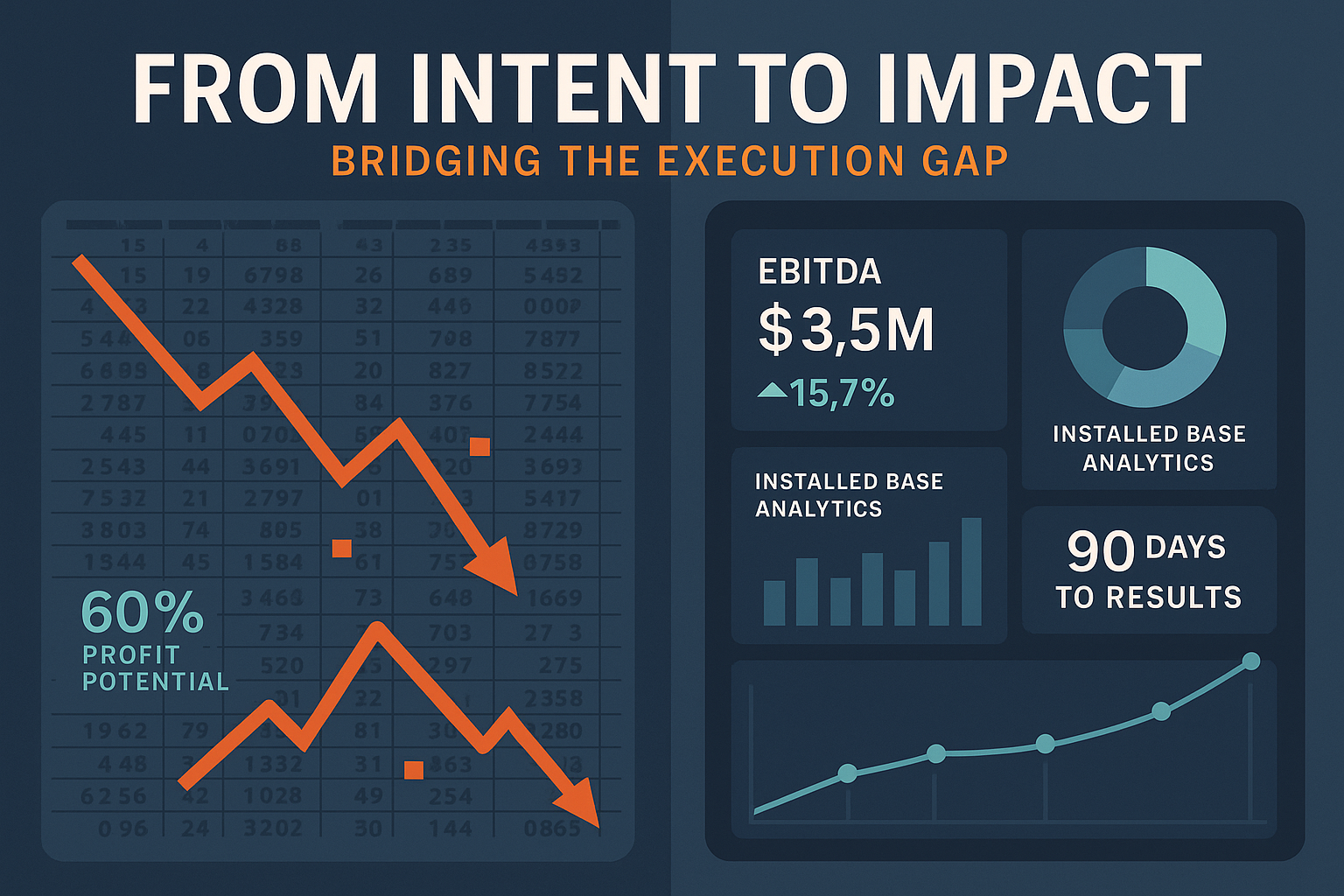

When private equity firms acquire industrial OEMs, the investment thesis looks bulletproof: unlock recurring revenue from the installed base, expand aftermarket margins, and drive sustainable EBITDA growth. It’s compelling on paper. Six months post-close, though, operating partners face a different story—the aftermarket engine promised during diligence is still idling in

6 PackExpo 2025 Observations That Define the Future of Manufacturing

Something felt different at PackExpo 2025. The energy was there demos running, conversations flowing but underneath the optimism, a pattern kept emerging in conversations with OEM leaders across the show floor. As Entytle’s CEO Vivek Joshi noted in his own reflections from PackExpo, the tone this year was noticeably pragmatic.

The Untapped Value Lever in Private Equity Portfolios: Aftermarket Intelligence

Every operating partner knows the feeling. You’re sitting in a quarterly portfolio review, looking at yet another OEM that’s underperforming on aftermarket revenue again. The management team acknowledges the opportunity. They’ve even invested in “digital transformation” initiatives. But somehow, the aftermarket remains a black box. Parts sales plateau. Service contracts

Intelligent Account Planning: Unlocking Aftermarket Growth with Installed Base Data

Why are so many industrial OEMs missing out on the full value of their aftermarket?For decades, account planning in industrial machinery has relied on experience, intuition, and fragmented data scattered across CRMs, ERPs, and spreadsheets. But as aftermarket moves from a support function to the primary profit driver, this approach

Why Most Aftermarket Teams Are Flying Blind – And What It’s Costing You Now

Building Reliable Installed Base Systems Through Effective Data Engineering

Data Engineering is central to building and maintaining effective installed base management systems. The process involves collecting, integrating, and organizing data from various sources to provide a comprehensive view of assets, operations, and service activities. This article examines the technical challenges and approaches to Data Engineering in the context of

How to unlock Wallet Share with your Service BOM? – Let’s find out

Are You Missing Service BOM-Based Revenue? Here’s Why You Might Be For most Industrial OEMs, the real revenue isn’t just in selling the equipment — it’s in the aftermarket. Spare parts, services, upgrades, maintenance kits — these are recurring, high-margin opportunities. But most OEMs are leaving serious money on the

From Deal Thesis to EBITDA Reality: Why PE-Backed OEMs Must Fix Their Aftermarket Execution

When private equity firms acquire industrial OEMs, the investment thesis looks bulletproof: unlock recurring revenue from the installed base, expand aftermarket margins, and drive sustainable EBITDA growth. It’s compelling on paper. Six months post-close, though, operating partners face a different story—the aftermarket engine promised during diligence is still idling in

6 PackExpo 2025 Observations That Define the Future of Manufacturing

Something felt different at PackExpo 2025. The energy was there demos running, conversations flowing but underneath the optimism, a pattern kept emerging in conversations with OEM leaders across the show floor. As Entytle’s CEO Vivek Joshi noted in his own reflections from PackExpo, the tone this year was noticeably pragmatic.

The Untapped Value Lever in Private Equity Portfolios: Aftermarket Intelligence

Every operating partner knows the feeling. You’re sitting in a quarterly portfolio review, looking at yet another OEM that’s underperforming on aftermarket revenue again. The management team acknowledges the opportunity. They’ve even invested in “digital transformation” initiatives. But somehow, the aftermarket remains a black box. Parts sales plateau. Service contracts

Intelligent Account Planning: Unlocking Aftermarket Growth with Installed Base Data

Why are so many industrial OEMs missing out on the full value of their aftermarket?For decades, account planning in industrial machinery has relied on experience, intuition, and fragmented data scattered across CRMs, ERPs, and spreadsheets. But as aftermarket moves from a support function to the primary profit driver, this approach

Get our bi-monthly blog digest! Sign up now to receive it in your email inbox!

From Deal Thesis to EBITDA Reality: Why PE-Backed OEMs Must Fix Their Aftermarket Execution

When private equity firms acquire industrial OEMs, the investment thesis looks bulletproof: unlock recurring revenue from the installed base, expand aftermarket margins, and drive sustainable EBITDA growth. It’s compelling on paper. Six months post-close, though, operating partners face a different story—the aftermarket engine promised during diligence is still idling in

6 PackExpo 2025 Observations That Define the Future of Manufacturing

Something felt different at PackExpo 2025. The energy was there demos running, conversations flowing but underneath the optimism, a pattern kept emerging in conversations with OEM leaders across the show floor. As Entytle’s CEO Vivek Joshi noted in his own reflections from PackExpo, the tone this year was noticeably pragmatic.

The Untapped Value Lever in Private Equity Portfolios: Aftermarket Intelligence

Every operating partner knows the feeling. You’re sitting in a quarterly portfolio review, looking at yet another OEM that’s underperforming on aftermarket revenue again. The management team acknowledges the opportunity. They’ve even invested in “digital transformation” initiatives. But somehow, the aftermarket remains a black box. Parts sales plateau. Service contracts

Intelligent Account Planning: Unlocking Aftermarket Growth with Installed Base Data

Why are so many industrial OEMs missing out on the full value of their aftermarket?For decades, account planning in industrial machinery has relied on experience, intuition, and fragmented data scattered across CRMs, ERPs, and spreadsheets. But as aftermarket moves from a support function to the primary profit driver, this approach

“Get our bi-monthly blog digest! Sign up now to receive it in your email inbox!

Error: Contact form not found.