Something felt different at PackExpo 2025. The energy was there demos running, conversations flowing but underneath the optimism, a pattern kept emerging in conversations with OEM leaders across the show floor.

As Entytle’s CEO Vivek Joshi noted in his own reflections from PackExpo, the tone this year was noticeably pragmatic. The industrial slowdown has hit nearly every OEM segment, and the conversations were less about “what’s next” and more about “how to adapt.” Over dozens of meetings with packaging, material handling, and processing equipment manufacturers, a consistent theme surfaced: the old playbook of depending on new equipment sales is breaking down and the next growth curve lies in how well OEMs understand, manage, and monetize their installed base.

Across three days and countless conversations, six trends stood out—clear signals that the manufacturing landscape is shifting under our feet.

1. Installed Base Is Massive — and Undermanaged

Every OEM leader had the same problem: they’ve sold thousands of machines, but they don’t know where those machines are, how they’re being used, or when they’ll need service.

One VP of Aftermarket Services said it plainly: “We have a multi-billion dollar installed base, but we’re flying blind on most of it.”

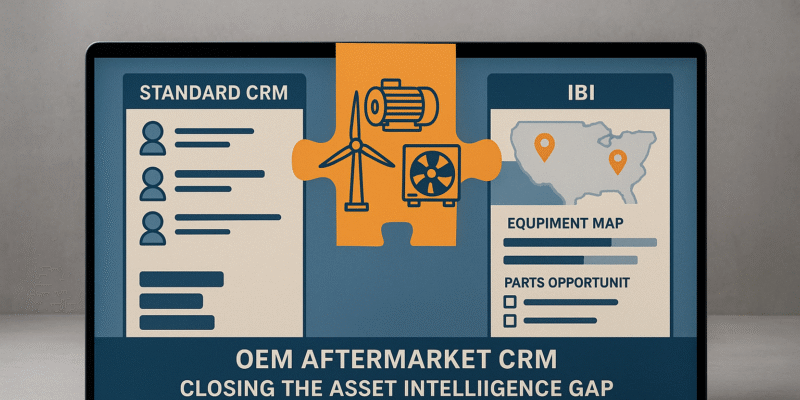

The issue isn’t missing data, it’s fragmented data. Customer records sit in CRM systems. Machine configurations live in ERP platforms. Service history gets logged in field service tools. Warranty information hides in spreadsheets. Nothing connects.

This isn’t just operationally inefficient. It’s a strategic gap. Without unified visibility into deployed assets, when they were commissioned, and what configuration they’re running, OEMs can’t proactively engage customers. They’re stuck waiting for breakdowns or phone calls.

Companies getting this right treat their installed base like a living asset, not a static archive. They’re building unified data layers that consolidate machine intelligence, customer history, and lifecycle insights. That foundation unlocks predictive maintenance, targeted upsell opportunities, and retention strategies that kick in before competitors get a chance.

2. OEM Sales Are Slowing Down

New equipment sales are soft and they’re likely staying that way through 2025.

Global machinery production contracted 2.1% in 2024, according to Interact Analysis. Construction equipment manufacturers are forecasting a 5-10% revenue decline in 2025 in the U.S.

The reasons are familiar. Higher interest rates make capital equipment more expensive to finance. End-user industries food and beverage, CPG, pharma are cautious about new projects. Customers are running existing lines longer and deferring expansions.

But here’s what’s keeping OEMs stable: aftermarket revenue is holding strong. In many cases, it’s growing.

Customers may not be buying new machines, but they’re still running the ones they have and those machines need parts, consumables, upgrades, and support. For OEMs with strong service operations, this industrial slowdown isn’t an existential crisis. It’s a forcing function to double down on recurring revenue.

The leaders I spoke with aren’t panicking. They’re pivoting shifting resources toward installed base monetization, expanding service offerings, and building digital tools that make it easier for customers to order parts and schedule maintenance. When OEM Sales Slow Down, the winners are those who already have a plan for the installed base.

3. AI Adoption Is Talk, Not Action

AI signage was everywhere at PackExpo 2025 in booth graphics, demo videos, pitch decks. But when I asked OEM leaders what they’re actually doing with AI, the answers were surprisingly muted.

Most companies are experimenting. They’ve launched pilots for predictive maintenance algorithms, customer service chatbots, or quality control vision systems. A few are using AI to optimize production schedules or analyze warranty claims.

But very few have AI systems in production driving measurable business outcomes.

The gap between aspiration and execution comes down to three things: data readiness, organizational alignment, and use case clarity.

AI models need clean, structured data. But as we’ve established, most OEMs don’t have that. Their installed base data is fragmented. Service records are inconsistent. Customer engagement history is scattered. You can’t train effective models on chaos.

Organizationally, AI initiatives often lack executive sponsorship or cross-functional buy-in. IT wants ownership. Engineering thinks they should lead. Marketing views it as a customer experience play. Without a clear owner and unified strategy, projects stall.

Then there’s the use case problem. Too many OEMs chase AI because it’s trendy, not because they’ve identified a specific, high-value problem that AI uniquely solves. The result? Proofs of concept that never scale.

OEMs getting traction with AI aren’t starting with technology. They’re starting with problems—like reducing unplanned downtime or improving first-time fix rates—then building the data infrastructure and workflows needed to support an AI-driven solution.

4. Talent Crunch Is Accelerating

The workforce conversation at PackExpo wasn’t about hiring challenges. It was about survival.

Nearly one-fourth of the manufacturing workforce is 55 or older, according to U.S. Census data. The U.S. faces a shortfall of 1.9 million manufacturing workers by 2033, with 3.8 million positions opening up but nearly half potentially going unfilled, according to The Manufacturing Institute.

Senior field service engineers, machine builders, and applications specialists—the people who know the machines inside and out—are retiring, and they’re taking decades of institutional knowledge with them.

One service director mentioned his team’s average age is in the mid-50s. Another said they’ve lost three master technicians in 18 months and haven’t hired a single replacement.

Younger workers aren’t lining up. Manufacturing jobs are perceived as low-tech, manual, and unstable. The reality is far different—today’s service engineers diagnose complex mechatronic systems, use IoT sensors, and troubleshoot PLC logic—but the perception problem persists.

This creates a vicious cycle. Fewer technicians means slower response times, lower customer satisfaction, and revenue leakage. It also makes it harder to scale service or expand into new markets.

OEMs addressing this aren’t just raising salaries. They’re rethinking how knowledge is captured, shared, and applied. They’re building digital knowledge bases, investing in augmented reality for remote support, and creating structured onboarding that accelerates time-to-competency.

The goal isn’t replacing people with technology. It’s arming the people you have with better tools so they can do more, faster, with greater confidence.

5. PE Pressure Is Rising

Private equity ownership has reshaped the OEM landscape, and that influence was clear at PackExpo 2025.

PE-backed OEMs face intense pressure to deliver EBITDA growth—and with new equipment sales slowing, that growth has to come from the aftermarket.

One CFO said his board expects the aftermarket to grow from 30% of total revenue to 50% within three years. Another mentioned a mandate to double service attach rates and reduce parts leakage by 25% in the next 18 months.

These aren’t stretch goals. They’re survival metrics. PE firms view aftermarket as more predictable, higher-margin revenue than capital equipment, and they’re pushing portfolio companies hard to capture it.

The challenge is that most OEMs aren’t set up for this. Their pricing models are outdated. Parts distribution is inefficient. They lack visibility into which customers buy from third-party suppliers. Sales teams are trained to sell machines, not service contracts.

OEMs winning here treat the aftermarket like a product line, not a cost center. They’re investing in systems that track installed base health, building digital commerce platforms for parts and consumables, and aligning sales compensation to reward recurring revenue—not just one-time deals.

6. Service Teams Are the Unsung Heroes

If there’s one group that deserves more recognition, it’s service and support teams.

While sales teams face pipeline pressure and engineering teams navigate product roadmaps, service teams keep customers operational—and loyal.

They’re the first call when a machine goes down. They build relationships at the plant level. They’re the face of the OEM when things go wrong, and they’re often why customers come back for upgrades, parts, and additional machines.

Yet in many organizations, service is still seen as reactive—a cost center that fixes things when they break. Top-performing OEMs have flipped that narrative. They see service as a growth engine.

They’re empowering service teams with better tools: mobile apps providing instant access to machine history, parts availability, and troubleshooting guides. Hence giving technicians authority to upsell on-site. They are tracking service KPIs like customer health scores, contract renewal rates, and Net Promoter Scores—not just fix times.

And they’re connecting service to broader business strategy. When a technician notices a machine running inefficiently, that insight flows back to engineering for product improvements. When a customer declines a service contract, that triggers a sales follow-up. Service isn’t siloed—it’s integrated.

The OEMs That Win Will Master Their Installed Base | PackExpo 2025

PackExpo 2025 made one thing clear: the future of manufacturing isn’t just about building better machines. It’s about managing the machines you’ve already built.

The OEMs that will lead the next cycle are investing in Installed Base Intelligence unified visibility into what’s deployed, where, and how it’s performing. They’re automating knowledge so it doesn’t walk out the door when a senior technician retires. They’re turning the aftermarket from reactive service into proactive revenue.

The industrial slowdown isn’t going away. But it’s not a death sentence either. It’s a reset. Companies that emerge stronger will be those that stopped treating their installed base as an archive and started treating it as an asset.

Ready to turn your installed base into your greatest competitive advantage? Learn how Entytle helps OEMs unlock revenue, reduce churn, and scale service operations with Installed Base Intelligence.