Struggling with Installed Base Data?

In the industrial sector, managing an installed base—tracking equipment, monitoring usage, maintaining service records, and predicting maintenance and parts needs—is a complex yet crucial task. Many Original Equipment Manufacturers (OEMs) struggle with disorganized and fragmented installed base data, leading to inefficiencies, missed opportunities, and customer dissatisfaction.

The Challenges of Installed Base Data

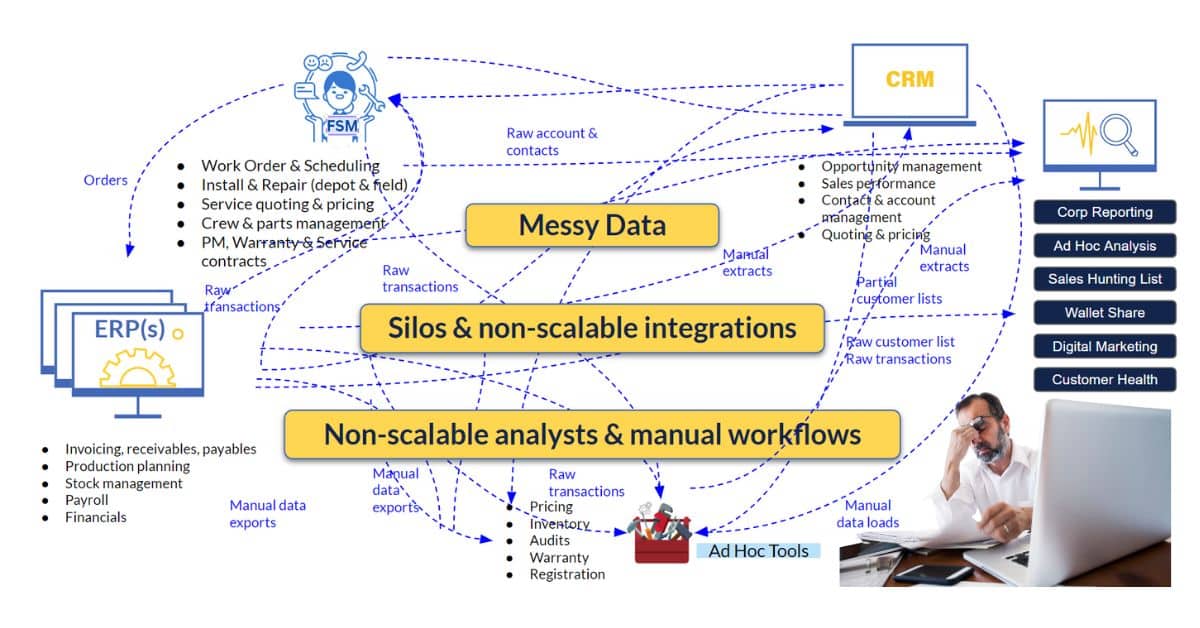

- Data Silos: Information about the installed base is often spread across multiple systems like CRM, ERP, and field service management (FSM) software. These silos prevent a holistic view of the data, making it difficult to access comprehensive insights.

- Inconsistent Data Quality: Data entries might be incomplete, outdated, or inaccurate. Poor data quality hampers decision-making and reduces the effectiveness of service operations.

- Complex Integration: Integrating data from various sources requires robust processes and governance. Without proper integration, the data remains fragmented and hard to use effectively.

- Scalability Issues: Maintaining data quality at scale is challenging. As the volume of data grows, so does the complexity of ensuring its accuracy and usability.

What is an Installed Base Platform?

An Installed Base Platform is a smart system that gathers, organizes, and analyzes the data that OEMs (Original Equipment Manufacturers) need to give customers the best experience. It’s a powerful tool specifically purpose built for Industrial OEMs.

Here’s what it does:

- Connects Systems: It links all data from all systems you use today, like your ERPs, CRM, FSM, data in spreadsheets and legacy systems.

- Unifies Data: It brings together all your account details, locations, contacts, equipment, service records, parts, and warranties into one place.

- Zooms In on Details: It helps you look closely at your data, from a large area down to a single piece of equipment at a customer’s location.

- Ensures Data Reliability: It cleans and organizes your data so you can trust it, without you having to do the hard work.

The Installed Base Platform makes workflows that involve customers more efficient. It uses cloud-based technology and AI (Artificial Intelligence) to give you a complete view of your installed base. It creates smart lists and automates tasks between different tools and systems. This makes your work faster and more productive, helping you handle more tasks and grow your business. The data is made available to other systems via open architecture so that every system and workflow in the organization can leverage clean data.

History of Entytle's Installed Base Platform

Entytle was born out of frustration with the state-of-the-art (or rather, the lack of) Aftermarket CRM systems. We couldn’t believe that in the 21st century, Aftermarket business leaders were “getting by” with spreadsheets, ad-hoc reports, or worse, no analytical insights into the behavior of their customers and assets. The cost of this approach is staggering. According to Gartner, data quality affects overall labor productivity by up to 20%. This is due to field teams engaging in fruitless outreach, missing installed base information, using incorrect parts, experiencing low first-time resolution rates, and more. According to Forbes, bad data costs US businesses a staggering $3.1 trillion annually, or 20% of their value.

After interviewing over 300 Aftermarket leaders in companies across the US and Europe, we realized there was a better way to make and save money from your Installed Base.

- What if you could pinpoint exactly which customers need attention and serve them completely and well? Instead of scattering your attention and resources across the entire Installed Base, thereby satisfying no one?

- What if you could have all the relevant information about these customers in a full 360-degree view of their interactions with you? Instead of running reports from multiple systems and cobbling them together?

- What if you could pre-empt service incidents for these customers to yield better outcomes? Instead of reacting to their “firefights” with attendant costs?

- What if this could help you connect with the “invisible 60%” to grow your wallet share? Instead of only focusing on the top 20%?

We learned that this is not only important and valuable but also possible, and that’s how the journey of the Installed Base Intelligence Platform began.

Why Do Industrial OEMs Need an Installed Base Platform?

An Installed Base Platform is an industrial OEM’s best hope for quickly adapting to the rapidly evolving market landscape.

An Installed Base Platform assembles and processes massive amounts of customer data using sophisticated, purpose-built algorithms to deliver highly qualified opportunities and actionable customer insights that your sales and service professionals can use right away. This, in turn, enables your teams to quickly build a pipeline, no matter what market conditions look like.

An Installed Base Platform does the heavy lifting for you, so you or your team don’t have to. It connects multiple siloed systems typical in a manufacturing setup (think ERP, CRM, service tools, etc.). It understands manufacturing concepts and can combine data from multiple systems meaningfully. To do this, it fixes errors, eliminates duplicates, and builds relationships between equipment, parts, locations, accounts, contacts, services, warranties, line items, and much more. Once data accuracy and reliability are established, manufacturing-specific opportunity-generation algorithms take over to create quick and long-term wins for your team. With an Installed Base Platform, your organization can transform raw, difficult data into actionable insights in a snap.

Customer Success Story

A global leader in packaging machine manufacturing achieved 42% increase in aftermarket revenue.

Customer Success Story

Learn how Entytle helped a packaging equipment manufacturer increase their aftermarket sales by 9.5% in 6 months by making their Installed Base data actionable.

Customer Success Story

Learn how Entytle helped a Water Pump manufacturer added $1.5M through targeted marketing campaigns by making their Installed Base data actionable.

Connect with our team and learn more about Entytle

- info@entytle.com

- 2301 W Anderson Ln, Austin, Texas 78757

Ready to take the next step?

Additional resources for you

- Industrial OEMs need an Installed Base Platform now more than ever…

- The value of your installed base is the value of your business

- How can Industrials use Installed Base data to boost revenue growth?

- Are BI tools a match for Installed Base Platform?

- Why Installed Base prospecting is broken for OEMs

- Industrials- Are you holding back your channel partners from better serving your Installed Base?

- What Does Maslow’s Hierarchy of Needs have to do with Industrial OEMs, Digitization of Customer Experience & Installed Base?