Imagine a scenario where Industrial aftermarket teams are constantly battling with poor data. This problem is pervasive and affects every part of the sales process. Every day Industrial aftermarket teams scrapples with inconsistent and inefficient data that makes it difficult for them to keep the track of inventory and pricing of the available spare parts. The aftermarket teams are forced to navigate through multiple sources from manual notes to spreadsheets to CRM/ERPs software, which leads to inefficiencies and confusion.

Does this scenario sound familiar?

Accurate and reliable parts data is crucial for Industrial OEMs to operate at a higher scale and with efficiency. Unfortunately, many OEMs struggle with managing their parts data which is scattered across various platforms/sources. This problem is compounded by mergers and acquisitions, which can lead further to inconsistencies/inefficiency and quality deterioration. To address this problem Industrials should prioritize the establishment of a comprehensive and consistent system for managing the parts data of Industrials. Clean and accurate data can reduce errors, improve efficiencies and ultimately, boost the bottom line of Industrial OEMs.

“Many OEMs struggle with managing their parts data which is scattered across various platforms/sources.”

So how one can identify messy parts of their data?

Messy parts data usually has the following data points-

- Non-standardized

- Have variations in numbering and data capture

- Have numerous data quality challenges

Why is clean parts data important for manufacturing?

- Pricing consistency: Clean parts data helps in pricing consistently. It also helps in merging many duplicate line items and helps in creating bulk orders and overarching contracts.

- Identify the right parts for their products: Clean parts data helps OEMs to identify the right parts for their products by providing them with accurate and complete information about each part. This helps to ensure that the right parts are used in the right places, which can help to reduce defects and improve customer satisfaction.

- Reduced cost by streamlining the parts ordering and delivery process: Clean parts data can help OEMs to streamline the parts ordering and delivery process by providing them with a single source of truth for all of their parts data. This can help in cost reduction and increased efficiency.

- Improve the quality of their products: Clean parts data can help OEMs to improve the quality of their products by identifying potential problems with parts before they are used in production. This can help to prevent defects and improve customer satisfaction.

- Comply with regulations: Clean parts data can help OEMs to comply with regulations by providing them with the information they need to track and manage their parts inventory. This can help in avoiding costly fines and penalties.

- Make better decisions: Clean parts data can help OEMs to make better decisions by providing them with accurate and up-to-date information about their parts inventory. This can help them to improve their operations and make better products.

The process of cleaning and improving the quality of parts data is crucial to ensure the efficiency, and accuracy of marketing operations. This involves scrutinizing data points such as parts name, parts number, parts of which BOMs, dimensions, materials, and specifications to guarantee that the parts are produced according to the right standards. It also entails evaluating sourcing vendors to optimize buying strategies. By carrying out data clean-up and quality improvement, manufacturers can enhance their supply chain performance, reduce the risk of errors and inconsistencies, and ultimately increase customer satisfaction.

OEMs have regional ERPs, In-House v/s vendor parts datasets, and legacy v/s new naming standards which oftentimes lead to messy parts data:

- Being Non-standardized

- Having variations in numbering and data capture

- Having various data quality challenges

Having low-quality part data also becomes a big hindrance to successful digital transformation. The digital transformation core element is digital data and if that is not good then we are dealing with garbage in garbage out.

Entytle Data Services for Parts Clean-up and Quality improvement

For a parts clean-up project that could take multiple months or even years for OEMs, Entytle Data Services could do it within a matter of weeks.

Utilizing our team of AI+Expert services who understand Manufacturing data well, and with our process-built technology and processes, we would be able to clean and standardize your parts data using some of the below techniques:

- Consolidating variations of vendor names

- Mining other sources & fields for part number data

- Standardizing data formats

- Matching & clustering based on numbers & descriptions

For a quick ramp-up, all we would need is a partner we could work with within your organization who could help us understand the challenges today and the expected results from the clean-up before we get started on working with your data from various sources.

What our Customers are saying

One of our customers wanted to implement a global pricing strategy but had messy parts data which led to inconsistencies in part data due to which the global pricing strategy was unfortunately stalled for them until the parts data was cleaned up and made consistently.

They used Entytle’s Data Services for Parts number analysis and quality improvement post which there was a 27% Improvement in part numbers which resulted in a better global pricing strategy. This enabled the team to eventually take Data-driven Parts pricing and consistent purchasing decisions.

If you want to learn more about this service, CONTACT US

Why choose Entytle Data Services?

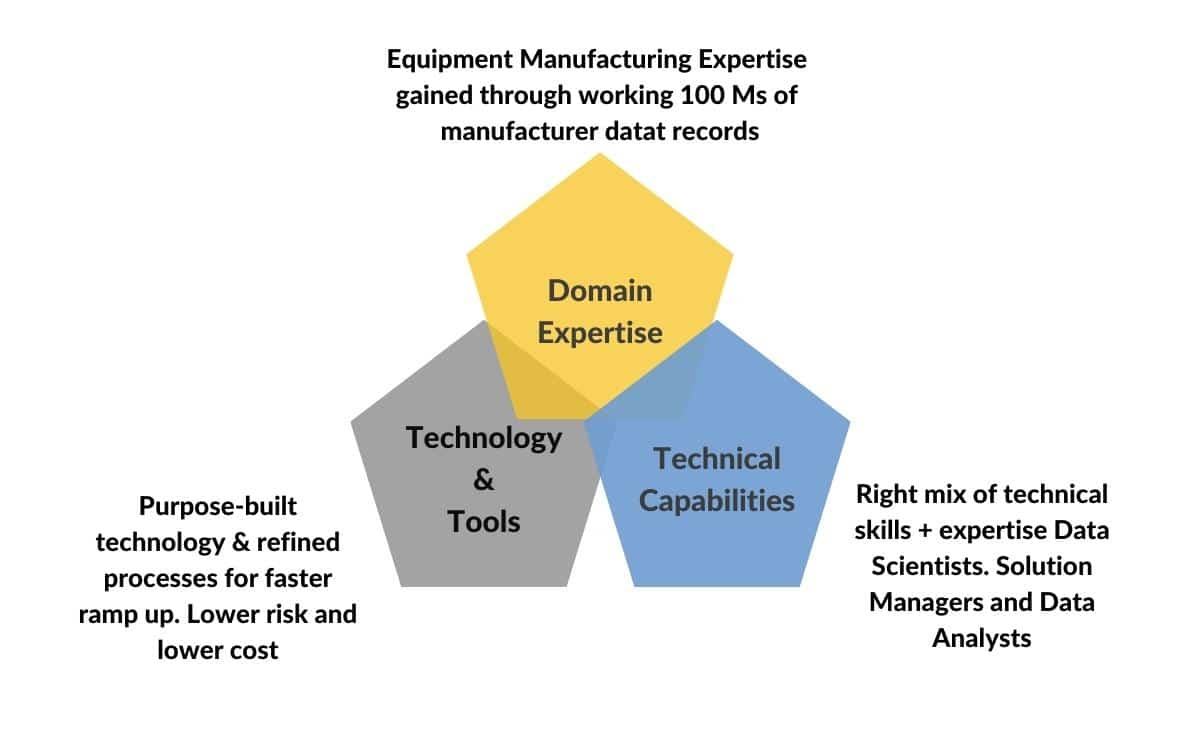

Entytle has the right mix of domain expertise, technology and tools, and technical capabilities by working on over 100M of manufacturer data records and various use cases. As we only focus on OEMs, we understand your data well enough that we could ramp up projects with a lower cost as opposed to in-house teams.

In conclusion, effective parts data management is a crucial part of modern manufacturing operations. The process of cleaning up and improving data helps to ensure accuracy, minimize errors, and inconsistencies, and increase customer satisfaction. By scrutinizing data points such as parts name, parts number, parts of which BOMs, dimensions, materials, and specifications, Industrials can optimize their buying strategies and enhance their supply chain performance. With the help of advanced data service solutions, Industrials can unlock the full potential of their data and can gain a competitive advantage in today’s competitive landscape.